A&P Mechanic

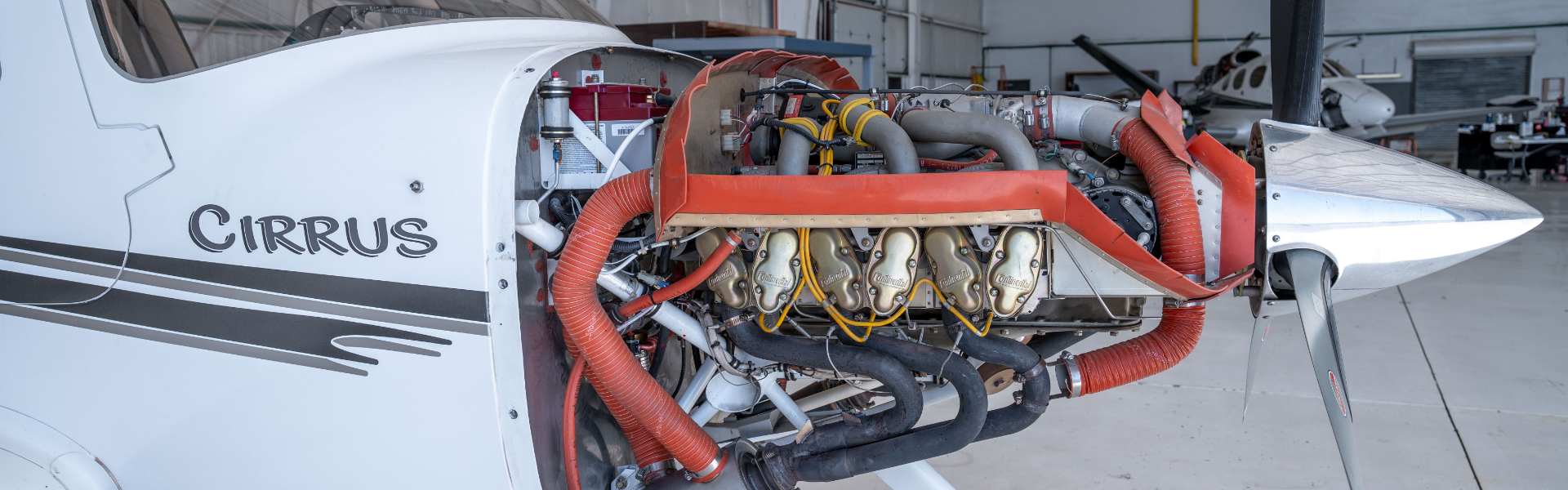

A&P Mechanics perform a variety of mechanical duties on various aircraft models including, but not limited to the following: diagnosis of malfunctions and required disassembly, rework, repair, replacement, reassembly, or adjustment of various aircraft systems to prepare aircraft for flight and delivery to customer.

We offer

A generous benefit package, competitive wages, and paid vacation and holidays. This is a tight-knit family with a collaborative and social environment. Leadership is compassionate, and transparent, and believes in empowering employees to achieve, not only for the business, but also their own personal success.

Core Schedule

- Days: Monday thru Friday

- Hours: 7:00 am – 4:00 pm

- Some on call or evening/weekend hours may be required.

You would be responsible for

- Performs intermediate/heavy maintenance tasks without supervision

- Performs airframe, powerplant and propeller repairs and modifications required to meet company and FAA requirements

- Performs routine inspections and troubleshooting, including airframe structures, engines, and aircraft systems

- Performs turbine engine troubleshooting, inspection, repair and engine run-ups

- Conducts airframe system, component changes and systems checkout

- Performs installation of service bulletins and kits on airframes and engines

- Ability to comprehend and complete all Aircraft Manufacturer Scheduled Maintenance items

- Removal and disassembly of defective parts; assembly and installation of replacement parts; and testing aircraft systems

- Interprets technical manuals, drawings, and blueprint

- Required to sign for work accomplished including troubleshooting deferred maintenance items and ensure proper recording of all maintenance tasks on company documents

- Building of customer invoices using labor calculations, purchase orders, and parts mark-up calculations

- Uses equipment such as tensiometers, micrometers, pressure gauges, dial gauges, vacuum gauges, timing lights, and a variety of hand tools to repair or modify systems or assemblies.

- Keep a constant watch for safety and ensure work performed adheres to the highest quality standards

- Monitor to reduce excessive cost of labor duplication

- Ensure proper and adequate equipment is used, acceptable parts or components are installed, and approved hardware or supplies are used

Minimum Qualifications

- A&P License is required

- Requires a minimum of 1 years’ experience with diversified jet, turboprop, piston, modification, aircraft/flight maintenance or airframe sheet metal maintenance. Must have experience in MROs

- Operates all power tools and equipment necessary to accomplish job assignment

- Preferred experience in a customer service facility performing inspections and repair of aircraft.

- Valid state driver’s license

- Requires use of arithmetic, blueprints, and specifications plus knowledge of jet and piston airframe and engine principles

- Flexibility in scheduling required

- Some travel required

- Must successfully pass background check and drug test

- Ability to read and respond to E-Mail communications